Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Milling machines are basically classified as vertical or. irregular surfaces by feeding the workpiece against a rotating. horizontal. These machines are also ...

Typology: Study Guides, Projects, Research

1 / 31

This page cannot be seen from the preview

Don't miss anything!

Chapter 8

Milling is the process of machining flat, curved, or Milling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as knee-type, cutter containing a number of cutting edges. The milling ram-type, manufacturing or bed type, and planer-type. Most machine consists basically of a motor driven spindle, which milling machines have self-contained electric drive motors, mounts and revolves the milling cutter, and a reciprocating coolant systems, variable spindle speeds, and power-operated adjustable worktable, which mounts and feeds the workpiece. table feeds

Knee-type milling machines are characterized by a vertically adjustable worktable resting on a saddle which is supported by a knee. The knee is a massive casting that rides vertically on the milling machine column and can be clamped rigidly to the column in a position where the milling head and milling machine spindle are properly adjusted vertically for operation.

The plain vertical machines are characterized by a spindle located vertically, parallel to the column face, and mounted in a sliding head that can be fed up and down by hand or power. Modern vertical milling machines are designed so the entire head can also swivel to permit working on angular surfaces,

The turret and swivel head assembly is designed for making precision cuts and can be swung 360° on its base. Angular cuts to the horizontal plane may be made with precision by setting the head at any required angle within a 180” arc.

The plain horizontal milling machine’s column contains the drive motor and gearing and a fixed position horizontal milling machine spindle. An adjustable overhead arm containing one or more arbor supports projects forward from the top of the column. The arm and arbor supports are used to stabilize long arbors. Supports can be moved along the overhead arm to support the arbor where support is desired depending on the position of the milling cutter or cutters.

The milling machine’s knee rides up or down the column on a rigid track. A heavy, vertical positioning screw beneath past the milling cutter. The milling machine is excellent for forming flat surfaces, cutting dovetails and keyways, forming and fluting milling cutters and reamers, cutting gears, and so forth. Many special operations can be performed with the attachments available for milling machine use.the knee is used for raising and lowering. The saddle rests upon the knee

and supports the worktable. The saddle moves in and out on a dovetail to control cross feed of the worktable. The worktable traverses to the right or left upon the saddle for feeding the workpiece past the milling cutter. The table may be manually controlled or power fed.

The basic difference between a universal horizontal milling machine and a plain horizontal milling machine is the addition of a table swivel housing between the table and the saddle of the universal machine. This permits the table to swing up to 45° in either direction for angular and helical milling operations. The universal machine can be fitted with various attachments such as the indexing fixture, rotary table, slotting and rack cutting attachments, and various special fixtures.

The ram-type milling machine is characterized by a spindle mounted to a movable housing on the column to permit positioning the milling cutter forward or rearward in a horizontal plane. Two popular ram-type milling machines are the universal milling machine and the swivel cutter head ram-type milling machine.

UNIVERSAL RAM-TYPE MILLING MACHINE

The universal ram-type milling machine is similar to the universal horizontal milling machine, the difference being, as its name implies, the spindle is mounted on a ram or movable housing.

The cutter head containing the milling machine spindle is attached to the ram. The cutter head can be swiveled from a vertical spindle position to a horizontal spindle position or can be fixed at any desired angular position between vertical and horizontal. The saddle and knee are hand driven for vertical and cross feed adjustment while the worktable can be either hand or power driven at the operator’s choice.

Milling machines require special safety precautions while being used. These are in addition to those safety precautions described in Chapter 1.

Do not make contact with the revolving cutter.

Place a wooden pad or suitable cover over the table surface to protect it from possible damage.

Use the buddy system when moving heavy attachments. Basic milling machine configurations are shown in Figure 8-1.

The pitch is determined tooth face is the forward forms the cutting edge.

by the number of teeth. facing surface of the tooth

The that

The cutting edge is the angle on each tooth that performs the cutting.

The land is the narrow surface behind the cutting edge on each tooth.

The rake angle is the angle formed between the face of the tooth and the centerline of the cutter. The rake angle defines the cutting edge and provides a path for chips that are cut from the workpiece.

The primary clearance angle is the angle of the land of each tooth measured from a line tangent to the centerline of the cutter at the cutting edge. This angle prevents each tooth from rubbing against the workpiece after it makes its cut.

This angle defines the land of each tooth and provides additional clearance for passage of cutting oil and chips.

The hole diameter determines the size of the arbor necessary to mount the milling cutter.

Plain milling cutters that are more than 3/4 inch in width are usually made with spiral or helical teeth. A plain spiral-tooth milling cutter produces a better and smoother finish and requires less power to operate. A plain helical- tooth milling cutter is especially desirable when milling an uneven surface or one with holes in it.

Types of Teeth

The teeth of milling cutters may be made for right-hand or left-hand rotation, and with either right-hand or left-hand

helix. Determine the hand of the cutter by looking at the face of the cutter when mounted on the spindle. A right-hand cutter must rotate counterclockwise; a left-hand cutter must rotate clockwise. The right-hand helix is shown by the flutes leading to the right; a left-hand helix is shown by the flutes leading to the left. The direction of the helix does not affect the cutting ability of the cutter, but take care to see that the direction of rotation is correct for the hand of the cutter

(Figure 8-4).

Saw Teeth

Saw teeth similar to those shown in Figure 8-3 are either straight or helical in the smaller sizes of plain milling cutters, metal slitting saw milling cutters, and end milling cutters. The cutting edge is usually given about 5 degrees primary clearance. Sometimes the teeth are provided with off-set nicks which break up chips and make coarser feeds possible.

Helical Milling Cutters

The helical milling cutter is similar, to the plain milling cutter, but the teeth have a helix angle of 45° to 60°. The steep helix produces a shearing action that results in smooth, vibration-free cuts. They are available for arbor mounting, or with an integral shank with or without a pilot. This type of helical cutter is particularly useful for milling elongated slots and for light cuts on soft metal. See Figure 8-5.

Metal Slitting Saw Milling Cutter

The metal slitting saw milling cutter is essentially a very thin plain milling cutter. It is ground slightly thinner toward the center to provide side clearance. These cutters are used for cutoff operations and for milling deep, narrow slots, and are made in widths from 1/32 to 3/16 inch.

Side Milling Cutters

Side milling cutters are essentially plain milling cutters with the addition of teeth on one or both sides. A plain side milling cutter has teeth on both sides and on the periphery. When teeth are added to one side only, the cutter is called a half-side milling cutter and is identified as being either a right-hand or left-hand cutter. Side milling cutters are generally used for slotting and straddle milling.

Interlocking tooth side milling cutters and staggered tooth side milling cutters are used for cutting relatively wide slots with accuracy (Figure 8-6). Interlocking tooth side milling cutters can be repeatedly sharpened without changing the width of the slot they will machine.

After sharpening, a washer is placed between the two cutters to compensate for the ground off metal. The staggered tooth cutter is the most washer is placed between the two cutters to compensate for efficient type for milling slots where the depth exceeds the width.

End Milling Cutters

The end milling cutter, also called an end mill, has teeth on the end as well as the periphery. The smaller end milling cutters have shanks for chuck mounting or direct spindle mounting. End milling cutters may have straight or spiral flutes. Spiral flute end milling cutters are classified as left- hand or right-hand cutters depending on the direction of rotation of the flutes. If they are small cutters, they may have either a straight or tapered shank.

Corner Rounding Milling Cutter

The corner-rounding milling cutter is a formed tooth cutter used for milling rounded corners on workplaces up to and including one-quarter of a circle. The size of the cutter is specified by the radius of the circular form the cutter produces, such as concave and convex cutters generally used for such work as finishing spur gears, spiral gears, and worm wheels. They may also be used to cut ratchets and spline shafts.

Special Shaped-Formed Milling Cutter

Formed milling cutters have the advantage of being adaptable to any specific shape for special operations. The cutter is made specially for each specific job. In the field, a fly cutter is formed by grinding a single point lathe cutter bit for mounting in a bar, holder, or fly cutter arbor. The cutter can be sharpened many times without destroying its shape.

Selection of Milling Cutters

Consider the following when choosing milling cutters:

45° angular cuts may either be made with a 45° single- angle milling cutter while the workpiece is held in a swivel vise, or with an end milling cutter while the workpiece is set at the required angle in a universal vise.

The harder the material, the greater will be the heat that is generated in cutting. Cutters should be selected for their heat-resisting properties,

Use a coarse-tooth milling cutter for roughing cuts and a finer-toothed milling cutter for light cuts and finishing operations.

When milling stock to length, the choice of using a pair of side milling cutters to straddle the workpiece, a single- side milling cutter, or an end milling cutter will depend upon the number of pieces to be cut.

Some operations can be done with more than one type of cutter such as in milling the square end on a shaft or

High-speed steel, stellite, and cemented carbide cutters

reamer shank. In this case, one or two side milling

have a distinct advantage of being capable of rapid

cutters, a fly cutter, or an end milling cutter may be used. However, for the majority of operations, cutters are production when used on a machine that can reach the proper speed. specially designed and named for the operation they are to accomplish.

The milling cutter should be small enough in diameter so that the pressure of the cut will not cause the workpiece to be sprung or displaced while being milled.

Size of Milling Cutter

In selecting a milling cutter for a particular job, choose one large enough to span the entire work surface so the job can be done with a single pass. If this cannot be done, remember that a small diameter cutter will pass over a surface in a shorter time than a large diameter cutter which is fed at the same speed. This fact is illustrated in Figure 8-9.

Care and Maintenance of Milling Cutters

The life of a milling cutter can be greatly prolonged by intelligent use and proper storage. General rules for the care and maintenance of milling cutters are given below.

New cutters received from stock are usually wrapped in oil paper which should not be removed until the cutter is used.

Take care to operate the machine at the proper speed for the cutter being used, as excessive speed will cause the cutter to wear rapidly from overheating.

Take care to prevent the cutter from striking the hard jaws of the vise, chuck, clamping bolts, or nuts.

Whenever practical, use the proper cutting oil on the cutter and workpiece during operations, since lubrication helps prevent overheating and cutter wear.

Keep cutters sharp. Dull cutters require more power to drive and this power, being transformed into heat, softens the cutting edges. Dull cutters should be marked as such and set aside for grinding. For further information on cutter grinding, refer to Chapter 5, Grinding Machines.

Thoroughly clean and lightly coat milling cutters with oil before storing.

Place cutters in drawers or bins so that their cutting edges will not strike each other. Hang small cutters on hooks or pegs, and set large cutters on end. Place taper and straight shank cutters in separate drawers, bins, or racks provided with suitable sized holes to receive the shanks.

Never operate a cutter backwards. Due to the clearance angle, the cutter will rub, producing a great deal of friction. Operating the cutter backward may result in cutter breakage.

ARBORS

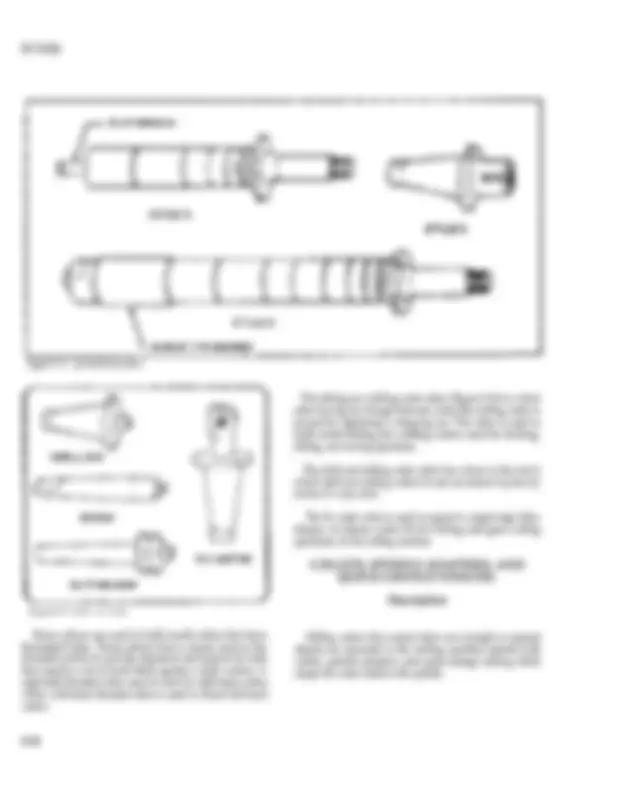

Milling machine arbors are made in various lengths and in standard diameters of 7/8,1,1 1/4, and 1 1/2 inch. The shank is made to fit the taper hole in the spindle while the other end is threaded.

NOTE: The threaded end may have left or right-handed threads.

The milling machine spindle may be self-holding or self- releasing. The self-holding taper is held in the spindle by the high wedging force. The spindle taper in most milling machines is self-releasing; tooling must be held in place by a draw bolt extending through the center of the spindle.

Arbors are supplied with one of three tapers to fit the milling machine spindle: the Standard Milling Machine taper, the Brown and Sharpe taper, and the Brown and Sharpe taper with tang (Figure 8-10).

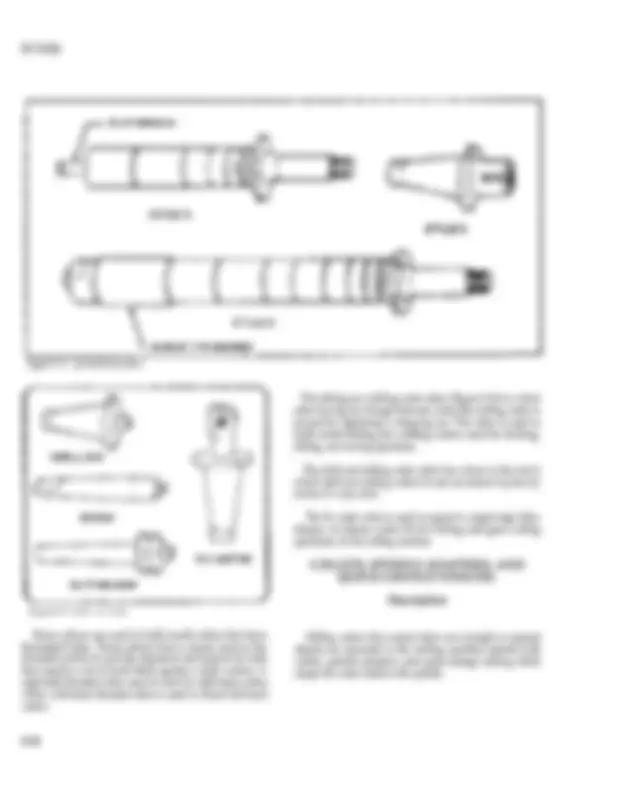

The slitting saw milling cutter arbor (Figure 8-14) is a short arbor having two flanges between which the milling cutter is secured by tightening a clamping nut. This arbor is used to hold metal slitting saw milling cutters used for slotting, slitting, and sawing operations.

The shell end milling cutter arbor has a bore in the end in which shell end milling cutters fit and are locked in place by means of a cap screw.

The fly cutter arbor is used to support a single-edge lathe, shaper, or planer cutter bit for boring and gear cutting operations on the milling machine.

COLLETS, SPINDLE ADAPTERS, AND QUICK-CHANGE TOOLING

Description

Screw arbors are used to hold small cutters that have (^) Milling cutters that contain their own straight or tapered threaded holes. These arbors have a taper next to the threaded portion to provide alignment and support for tools

shanks are mounted to the milling machine spindle with

that require a nut to hold them against a taper surface. A

collets, spindle adapters, and quick-change tooling which adapts the cutter shank to the spindle. right-hand threaded arbor must be used for right-hand cutters while a left-hand threaded arbor is used to mount left-hand cutters.

Collets

A collet is a form of a sleeve bushing for reducing the size of the hole in the milling machine spindle so that small shank tools can be fitted into large spindle recesses (Figure 8-15). They are made in several forms, similar to drilling machine sockets and sleeves, except that their tapers are not alike.

Spindle Adapters

A spindle adapter is a form of a collet having a standardized spindle end. They are available in a wide variety of sizes to accept cutters that cannot be mounted on arbors. They are made with either the Morse taper shank or the Brown and Sharpe taper with tang having a standard spindle end (Figure 8-16).

Chuck Adapter

A chuck adapter (Figure 8-17) is used to attach chucks to milling machines having a standard spindle end. The collet holder is sometimes referred to as a collet chuck. Various forms of chucks can be fitted to milling machines spindles for holding drills, reamers, (^) and small cutters for special operations.

Quick-Change Tooling

The quick-change adapter mounted on the spindle nose is used to speed up tool changing. Tool changing with this system allows you to set up a number of milling operations such as drilling, end milling, and boring without changing the setup of the part being machined. The tool holders are mounted and removed from a master holder mounted to the machine spindle by means of a clamping ring (Figure 8-18).

This attachment converts the horizontal spindle of a horizontal milling machine to a vertical spindle. It is clamped to the column and driven from the horizontal spindle. It incorporates provisions for setting the head at any angle, from the vertical to the horizontal, in a plane at right angles to the machine spindle. End milling and face milling are more easily accomplished with this attachment, because the cutter and the surface being cut are in plain view.

This device is similar to the vertical spindle attachment but is more versatile. The butterhead can be swiveled to any angle in any plane, whereas the vertical spindle attachment only rotates in one place from horizontal to vertical.

This attachment consists of a circular worktable containing T-slots for mounting workplaces. The circular table revolves on a base attached to the milling machine worktable. The attachment can be either hand or power driven, being connected to the table drive shaft if power driven. It may be used for milling circles, angular indexing, arcs, segments, circular slots, grooves, and radii, as well as for slotting internal and external gears. The table of the attachment is divided in degrees (Figure 8-20). advances twice the amount shown on the micrometer dial.

An efficient and positive method of holding workplaces to

Boring, an operation that is too often restricted to a lathe, can be done easily on a milling machine. The offset boring head is an attachment that fits to the milling machine spindle and permits most drilled holes to have a better surface finish and greater diameter accuracy.

Figure 8-21 shows an offset boring head. Note that the boring bar can be adjusted at a right angle to the spindle axis. This feature makes it possible to position the boring cutter accurately to bore holes of varying diameters.

This adjustment is more convenient than adjusting the cutter in the boring bar holder or changing the boring bar. Another advantage of the offset boring head is the fact that a graduated micrometer collar allows the tool to be moved accurately a specified amount (usually in increments of 0.001) without the use of a dial indicator or other measuring device.

NOTE: On some boring heads, the reading on the tool slide is a direct reading. On other boring heads, the tool slide

the milling machine table is important if the machine tool is to be used to its fullest advantage. The most common methods of holding are clamping a workpiece to the table, clamping a workpiece to the angle plate, clamping the workpiece in fixtures, holding a workpiece between centers, holding the workpiece in a chuck, and holding the workpiece in a vise. Page 4-13 of this manual shows a variety of mounting and holding devices. Regardless of the method used in holding, there are certain factors that should be observed in every case. The workpiece must not be sprung in clamping, it must be secured to prevent it from springing or moving away from the cutter, and it must be so aligned that it may be correctly machined T-slots, Milling machine worktables are provided with several T-slots which are used either for clamping and locating the workpiece itself or for

mounting the various holding devices and attachments. These T-slots extend the length of the table and are parallel to its line of travel. Most milling machine attachments, such as vises and index fixtures, have keys or tongues on the underside of their bases so that they may be located correctly in relation to the T-slots.

Clamping Workpieces to the Table

When clamping a workpiece to the worktable of the milling machine, the table and the workpiece should be free from dirt and burrs. Workpieces having smooth machined surfaces may be camped directly to the table, provided the cutter does not come in contact with the table surface during milling. When clamping workplaces with unfinished surfaces in this way, the table face should be protected from damage by using a shim under the workpiece. Paper, plywood, and sheet metal are shim materials. Clamps should be located on both sides of the workpiece if possible to give a full bearing surface. These clamps are held by T-slot bolts inserted in the T-slots of the table. Clamp supports must be the same height as the workpiece. Never use clamp supports that are lower than the workpiece. Adjustable step blocks are extremely useful to raise the clamps, as the height of the clamp bar may be adjusted to ensure maximum clamping pressure. Clamping bolts should be placed as near to the workpiece as possible so that the full advantage of the fulcrum principle may be obtained. When it is necessary to place a clamp on an overhanging part, a support should be provided between the overhang and the table to prevent springing or possible breakage. A stop should be placed at the end of the workpiece where it will receive the thrust of the cutter when heavy cuts are being taken.

Clamping a Workpiece to the Angle Plate

Workpieces clamped to the angle plate may be machined with surfaces parallel, perpendicular, or at an angle to a given surface. When using this method of holding a workpiece, precautions should be taken similar to those mentioned for clamping work directly to the table. Angle plates are either adjustable or nonadjustable and are generally held in alignment by keys or tongues that fit into the table T-slots.

Clamping Workpieces in Fixtures

Fixtures are generally used in production work where a number of identical pieces are to be machined. The design of the fixture depends upon the shape of the piece and the operations to be performed. Fixtures are always constructed

to secure maximum clamping surfaces and are built to use a minimum number of clamps or bolts in order to reduce the setup time required. Fixtures should always be provided with keys to assure positive alignment with the table T-slots.

Holding Workpieces Between Centers

The indexing fixture is used to support workplaces which are centered on both ends. When the piece has been pre- viously reamed or bored, it may be pressed upon a mandrel and then mounted between the centers.

Two types of mandrels may be used for mounting workplaces between centers. The solid mandrel is satisfactory for many operations, while one having a shank tapered to fit into the index head spindle is preferred in certain cases.

A jackscrew is used to prevent springing of long slender workplaces held between centers or workplaces that extend some distance from the chuck.

Workpieces mounted between centers are fixed to the index head spindle by means of a lathe dog. The bent tail of the dog should be fastened between the setscrews provided in the driving center clamp in such a manner as to avoid backlash and prevent springing the mandrel. When milling certain types of workpieces, a milling machine dog is held in a flexible ball joint which eliminates shake or spring of the dog or the workpiece. The flexible ball joint allows the tail of the dog to move in a radius along the axis of the workpiece, making it particularly useful in the rapid milling of tapers.

Holding Workpieces in a Chuck

Before screwing the chuck to the index head spindle, it should be cleaned and any burrs on the spindle or chuck removed. Burrs may be removed with a smooth-cut, three cornered file or scraper, while cleaning should be accomplished with a piece of spring steel wire bent and formed to fit the angle of the threads. The chuck should not be tightened on the spindle so tightly that a wrench or bar is required to remove it. Cylindrical workplaces held in the universal chuck may be checked for trueness by using a test indicator mounted upon a base resting upon the milling machine table. The indicator point should contact the circumference of small diameter workpieces, or the circum- ference and exposed face of large diameter pieces. While checking, the workpiece should be revolved by rotating the index head spindle.

Indexing

Indexing is the process of evenly dividing the circumference of a circular workpiece into equally spaced divisions, such as in cutting gear teeth, cutting splines, milling grooves in reamers and taps, and spacing holes on a circle. The index head of the indexing fixture is used for this purpose.

Index Head

The index head of the indexing fixture (Figure 8-19) contains an indexing mechanism which is used to control the rotation of the index head spindle to space or divide a workpiece accurately. A simple indexing mechanism consists of a 40-tooth worm wheel fastened to the index head spindle, a single-cut worm, a crank for turning the wormshaft, and an index plate and sector. Since there are 40 teeth in the worm wheel, one turn of the index crank causes the worm, and consequently, the index head spindle to make 1/40 of a turn; Whenever possible, the workpiece should be clamped in so 40 turns of the index crank revolve the spindle one full the center of the vise jaws. However, when necessary to mill a short workpiece which must be held at the end of the vise, a spacing block of the same thickness as the piece should be placed at the opposite end of the jaws. This will avoid strain on the movable jaw and prevent the piece from slipping. If the workpiece is so thin that it is impossible to let it extend over the top of the vise, hold down straps are generally used. See Figure 8-24. These straps are hardened pieces of steel, having one vertical side tapered to form an angle of about 92° with the bottom side and the other vertical side tapered to a narrow edge. By means of these tapered surfaces, the

turn.

Index Plate

The indexing plate (Figure 8-25) is a round plate with a series of six or more circles of equally spaced holes; the index pin on the crank can be inserted in any hole in any circle. With the interchangeable plates regularly furnished with most index heads, the spacing necessary for most gears, boltheads, milling cutters, splines, and so forth can be obtained. The following sets of plates are standard workpiece is forced downward into the parallels, holding (^) equipment: them firmly and leaving the top of the workpiece fully exposed to the milling cutter.

Brown and Sharpe type consists of 3 plates of 6 circles each drilled as follows:

Plate I -15, 16, 17, 18, 19, 20 holes

Plate 2-21, 23, 27, 29, 31, 33 holes

Plate 3-37, 39, 41, 43,47,49 holes

Cincinnati type consists of one plate drilled on both sides with circles divided as follows:

The same principle applies whether or not the divisions required divide equally into 40, For example, if it is desired to index for 6 divisions, 6 divided into 40 equals 6 2/3 turns; similarly, to index for 14 spaces, 14 divided into 40 equals 2 6/7 turns. These examples may be multiplied indefinitely and from them the following rule is derived: to determine the number of turns of the index crank needed to obtain one division of any number of equal divisions on the workpiece, divide 40 by the number of equal divisions desired (provided the worm wheel has 40 teeth, which is standard practice).

Direct Indexing First side -24, 25, 28, 30, 34, 37,38, 39,41,42,43 holes

Second side -46, 47, 49, 51, 53, 54, 57, 58, 59, 62, 66 holes

Sector

The sector (Figure 8-25) indicates the next hole in which the pin is to be inserted and makes it unnecessary to count holes when moving the index crank after each cut. It consists of two radial, beveled arms which can be set at any angle to each other and then moved together around the center of the index plate. Suppose that, as shown in Figure 8-25, it is desired to make a series of cuts, moving the index crank 1 1/4 turns after each cut. Since the circle illustrated has 20 holes, turn the crank one full turn plus five spaces after each cut, Set the sector arms to include the desired fractional part of a turn or five spaces between the beveled edges of its arms, as shown. If the first cut is taken with the index pin against the left-hand arm, to take the next cut, move the pin once against the right-hand arm of the sector. Before taking the second cut, move the arms so that the left-hand arm is again against the pin; this moves the right-hand arm another five spaces ahead of the pin. Then take the second cut, and repeat the operation until all the cuts have been completed.

NOTE: It is good practice always to index clockwise on the plate to eliminate backlash.

Plain Indexing

The following principles apply to basic indexing of workpieces:

Suppose it is desired to mill a project with eight equally spaced teeth. Since 40 turns of the index crank will turn the spindle one full turn, l/8th of 40 or 5 turns of the crank after each cut will space the gear for 8 teeth, If it is desired to space equally for 10 teeth, 1/10 of 40 or 4 turns would produce the correct spacing.

The construction of some index heads permits the worm to be disengaged from the worm wheel, making possible a quicker method of indexing called direct indexing. The index head is provided with a knob which, when turned through part of a revolution, operates an eccentric and disengages the worm.

Direct indexing is accomplished by an additional index plate fastened to the index head spindle. A stationary plunger in the index head fits the holes in this index plate. By moving this plate by hand to index directly, the spindle and the workpiece rotate an equal distance. Direct index plates usually have 24 holes and offer a quick means of milling squares, hexagons, taps, and so forth. Any number of divisions which is a factor of 24 can be indexed quickly and conveniently by the direct indexing method.

Differential Indexing

Sometimes, a number of divisions is required which cannot be obtained by simple indexing with the index plates regularly supplied. To obtain these divisions, a differential index head is used. The index crank is connected to the wormshaft by a train of gears instead of a direct coupling as with simple indexing. The selection of these gears involves calculations similar to those used in calculating change gear ratio for lathe thread cutting.

Indexing in Degrees

Workpieces can be indexed in degrees as well as fractions of a turn with the usual index head. There are 360 degrees in a complete circle and one turn of the index crank revolves the spindle 1/40 or 9 degrees. Therefore, 1/9 turn of the crank rotates the spindle 1 degree. Workpieces can therefore be indexed in degrees by using a circle of holes divisible by 9. For example, moving the crank 2 spaces on an 18-hole circle, 3 spaces on a 27-hole circle, or 4 spaces on a 36-hole circle

Milling Operations

Milling operations may be classified under four general headings as follows:

Face milling. Machining flat surfaces which are at right angles to the axis of the cutter,

Plain or slab milling. Machining flat surfaces which are parallel to the axis of the cutter.

Angular milling. Machining flat surfaces which are at an inclination to the axis of the cutter.

Form milling. Machining surfaces having an irregular outline.

Special Operations

Explanatory names, such as sawing, slotting, gear cutting, and so forth have been given to special operations. Routing is a term applied to milling an irregular outline while controlling the workpiece movement by hand feed. Grooving reamers and taps is called fluting. Gang milling is the term applied to an operation in which two or more milling cutters are used together on one arbor. Straddle milling is the term given to an operation in which two milling cutters are used to straddle the workpiece and mill both sides at the same time.

The speed of milling is the distance in FPM at which the circumference of the cutter passes over the work. The spindle RPM necessary to give a desired peripheral speed depends on the size of the milling cutter. The best speed is determined by the kind of material being cut and the size and type of cutter used, width and depth of cut, finish required, type of cutting fluid and method of application, and power and speed available are factors relating to cutter speed.

Factors Governing Speed

There are no hard and fast rules governing the speed of milling cutters; experience has shown that the following factors must be considered in regulating speed:

A metal slitting saw milling cutter can be rotated faster than a plain milling cutter having a broad face.

Cutters having undercut teeth (positive rake) cut more freely than those having radial teeth (without rake); hence, they may run at higher speeds.

Angle cutters must be run at slower speeds than plain or side cutters.

Cutters with inserted teeth generally will stand as much speed as a solid cutter.

A sharp cutter may be operated at greater speeds than a dull one.

A plentiful supply of cutting oil will permit the cutter to run at higher speeds than without cutting oil

Selecting Proper Cutting Speeds

The approximate values given in Table 8-1 in Appendix A may be used as a guide for selecting the proper cutting speed. If the operator finds that the machine, the milling cutter, or the workpiece cannot be handled suitably at these speeds, immediate readjustments should be made.

Table 8-1 lists speeds for high-speed steel milling cutters. If carbon steel cutters are used, the speed should be about one- half the recommended speed in the table. If carbide-tipped cutters are used, the speed can be doubled.

If a plentiful supply of cutting oil is applied to the milling cutter and the workpiece, speeds can be increased 50 to 100 percent. For roughing cuts, a moderate speed and coarse feed often give best results; for finishing cuts, the best practice is to reverse these conditions, using a higher speed and lighter feed.

Speed Computation

The formula for calculating spindle speed in revolutions per minute is as follows:

RPM = CSx D

Where RPM = Spindle speed (in revolutions per minute).

CS = cutting speed of milling cutter (in SFPM)

D = diameter of milling cutter (in inches)

For example, the spindle speed for machining a piece of steel at a speed of 35 SFPM with a cutter 2 inches in diameter is calculated as follows:

RPM= CSx4 = 35x4 = 140 D 2 2 = 70 RPM

Therefore, the milling machine spindle would be set for as near 70 RPM as possible.

Table 8-2 in Appendix A is provided to facilitate spindle speed computations for standard cutting speeds and standard milling cutters.

The rate of feed, or the speed at which the workpiece passes the cutter, determines the time required for cutting a job. In selecting the feed. there are several factors which should be considered.

Forces are exerted against the workpiece, the cutter, and their holding devices during the cutting process. The force exerted varies directly with the amount of feed and depth of cut. and in turn are dependent upon the rigidity and power of the machine. Milling machines are limited by the power they can develop to turn the cutter and the amount of vibration they can resist when using coarse feeds and deep cuts. The feed and depth of the cut also depend upon the type of milling cutter being used. For example. deep cuts or coarse feeds should not be attempted when using a small diameter end milling cutter. Coarse cutters with strong cutting teeth can be fed at a faster rate because the chips maybe washed out more easily by the cutting oil.

Coarse feeds and deep cuts should not be used on a frail workpiece if the piece is mounted in such a way that its holding device is not able to prevent springing or bending.

Experience and judgment are extremely valuable in selecting the correct milling feeds. Even though suggested rate tables are given. remember that these are suggestions only. Feeds are governed by many variable factors, such as the degree of finish required. Using a coarse feed, the metal is removed more rapidly but the appearance and accuracy of the surface produced may not reach the standard desired for the finished product. Because of this fact. finer feeds and increased speeds are used for finer. more accurate finishes. while for roughing. to use a comparatively low speed and heavy feed. More mistakes are made on overspeeding and underfeeding than on underspeeding and overfeeding.

Overspeeding may be detected by the occurrence of a squeaking. scraping sound. If vibration (referred to as chattering) occurs in the milling machine during the cutting process. the speed should be reduced and the feed increased. Too much cutter clearance. a poorly supported workpiece, or a badly worn machine gear are common causes of chattering.

Designation of Feed

The feed of the milling machine may be designated in inches per minute or millimeters per minute The milling feed is determined by multiplying the chip size (chip per tooth) desired (see Table 8-3 in Appendix A), the number of teeth on the cutter, and the revolutions per minute of the cutter.

Example: the formula used to find the workfeed in inches per minute.

IPM = CPTxNxRPM IPM = Feed rate in inches per minute. CPT = Chip pert N = Number of teeth per minute of the milling cutter.

The first step is to calculate the spindle speed before the feed rate can be calculated,

RPM = CSD 4 = 300 x 4 = 1,200 =2, D 1/2 0.

The second step is to calculate the feed rate.

IPM = CPT x N x RPM = 0.005 x 2 x 2, = 24

Therefore, the RPM for a l/2-inch-diameter end mill machining aluminum revolves at 2.400 RPM and the feed rate should be 24 inches per minute.

The formula used to find workfeed in millimeters per minute is the same as the formula used to find the feed in IPM, except that mm/min is substituted for IPM.

Direction of Feed

It is usually regarded as standard practice to feed the workpicce against the milling cutter. When the workpiece is fed against the milling cutter. the teeth cut under any scale on the workpiece surface and any backlash in the feed screw is taken up by the force of the cut. See Figure 8-26.