Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

An overview of various types of steel, including their composition, properties, and applications. Topics covered include ferrous alloys, carbon content classification, and the unique characteristics of low carbon (mild) steel, medium carbon steel, high carbon steel, and high speed steel.

What you will learn

Typology: Lecture notes

1 / 49

This page cannot be seen from the preview

Don't miss anything!

Ferrous Alloy

Steel

is an important constituent because of its ability to increase the hardness and

strength of the steel.

carbon content.

Low carbon steel (mild steel ) less then 0.30 % C

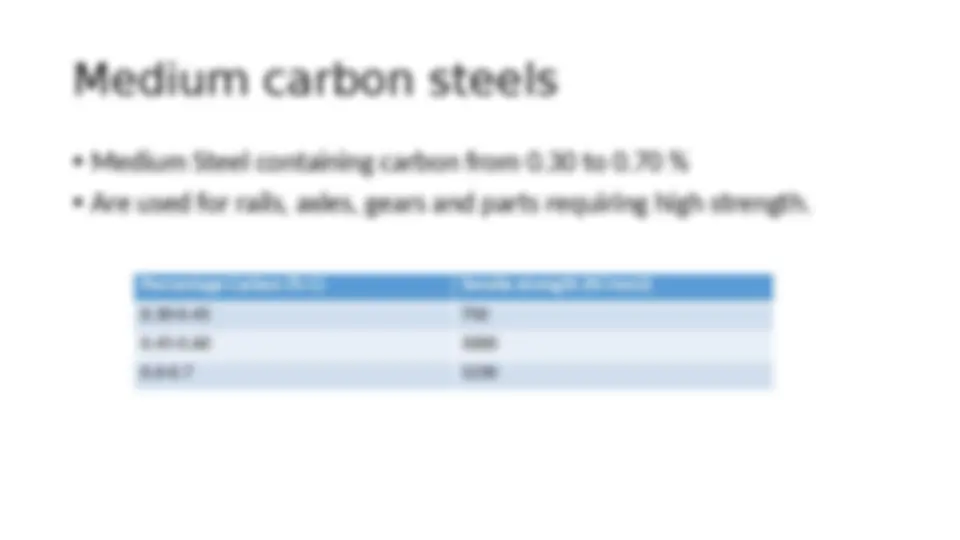

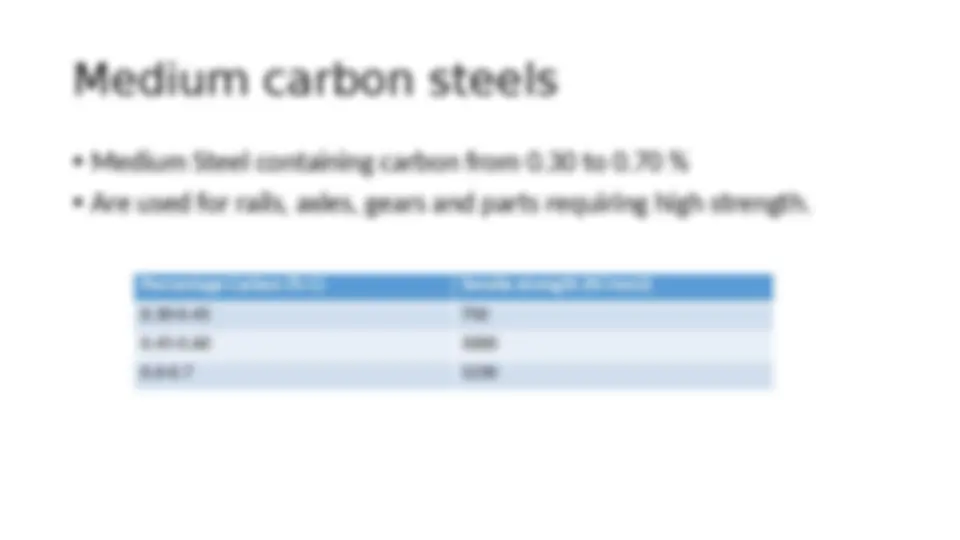

Medium carbon steel 0.30 to 0.70 % C

High carbon steel 0.70 to 2.0 C

When elements like Nickel, chromium, tungsten are present in sufficient quantity,

the steel is called “alloy steel”.

Mild steel

Properties

Application of mild steel

screw machine parts such as screws, nuts and bolts, storage tanks,

automobile frames, sheet.

machined, since the carbon content is low so heat treatment process

is ineffective.

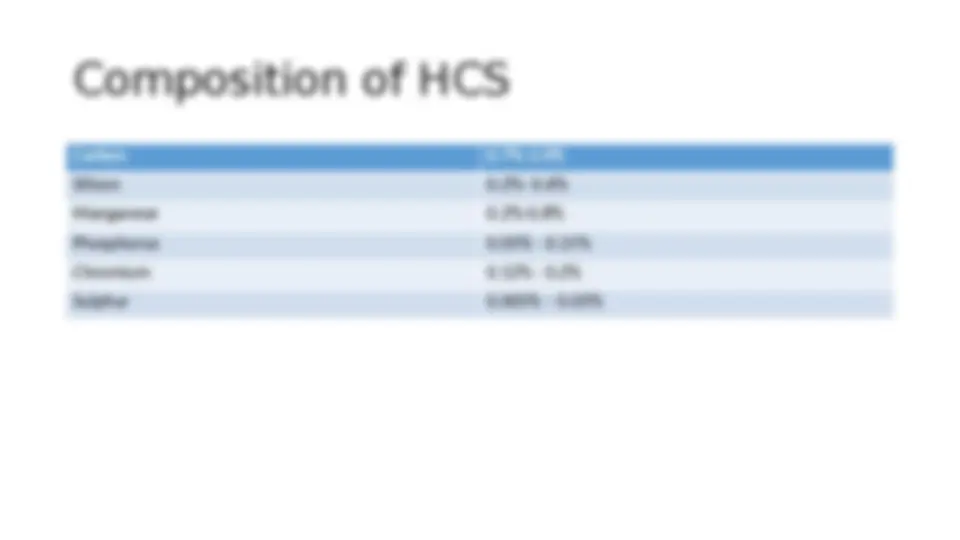

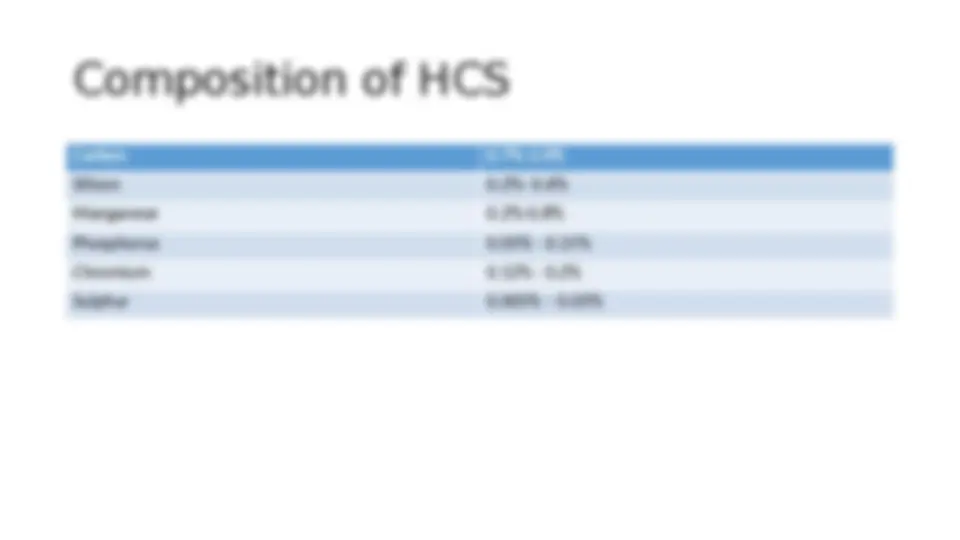

Composition of HCS

Carbon 0.7%-2.0%

Silicon 0.2%- 0.6%

Manganese 0.2%-0.8%

Phosphorus 0.05% - 0.15%

Chromium 0.12% - 0.2%

Sulphur 0.005% – 0.05%

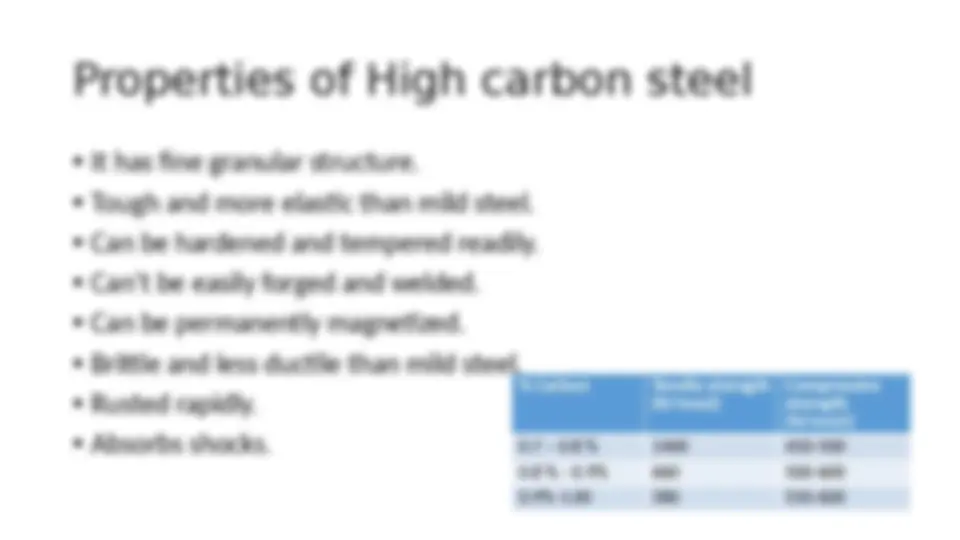

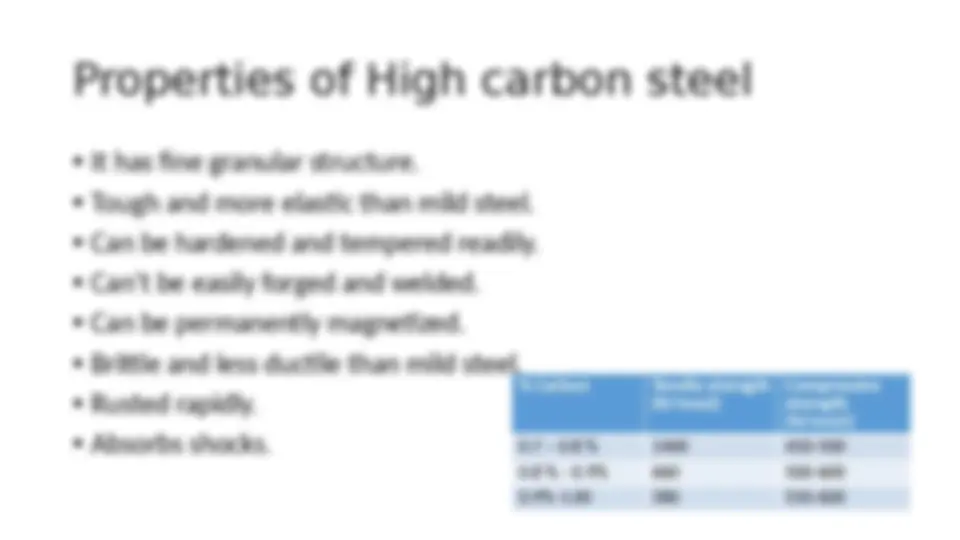

Uses of High carbon steel

drills, taps, hand tools, reamers and for abrasion-resisting properties.

so these are used to make products having high strength and

hardness.

This steel is also used for making product having edges, shear blades

and also for spring wire, wire rope.

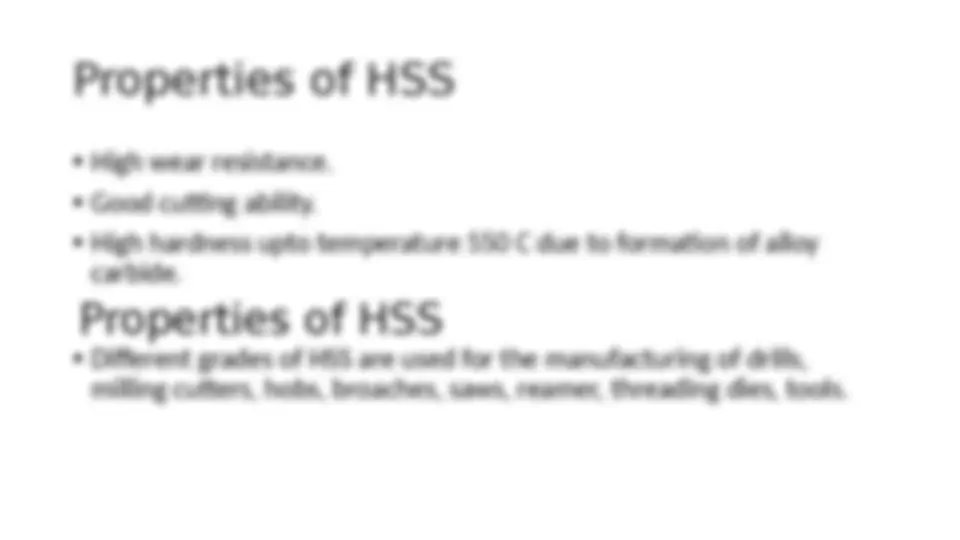

High speed steel (HSS)

alloying elements such as tungsten, molybdenum, chromium and

vanadium.

necessary for the tool.

and iron in steel which gives secondary hardening.