Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Size enlargement is an essential unit operation in particle technology that works opposite to size reduction. This process increases the size of particles using mechanical forces, pressure, temperature, or a combination of these methods. Industries such as food, agriculture, pharmaceutical, and construction heavily utilize size enlargement for better flowability and ease in handling. Three common methods include agitation, pressure compaction, and elevated temperatures.

What you will learn

Typology: Assignments

1 / 3

This page cannot be seen from the preview

Don't miss anything!

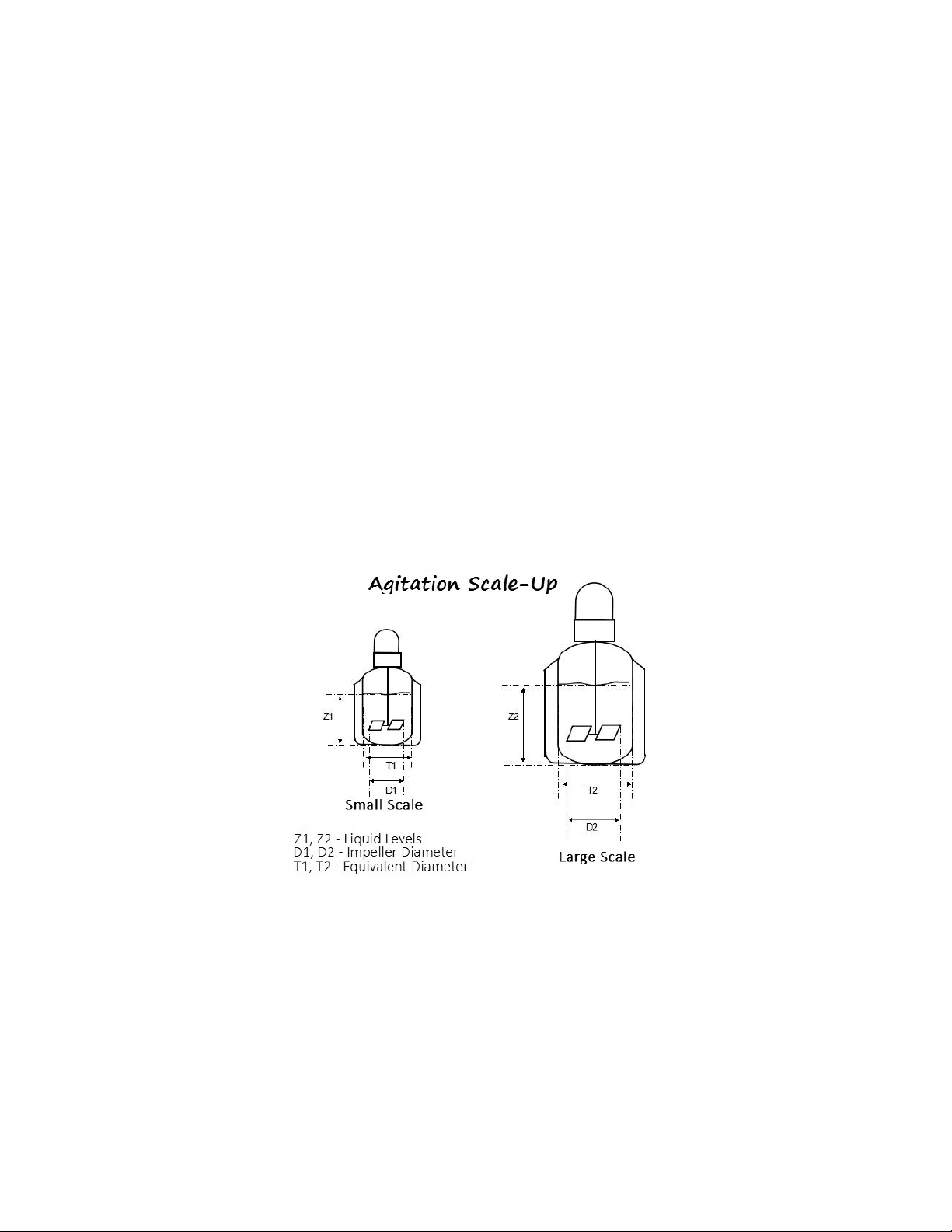

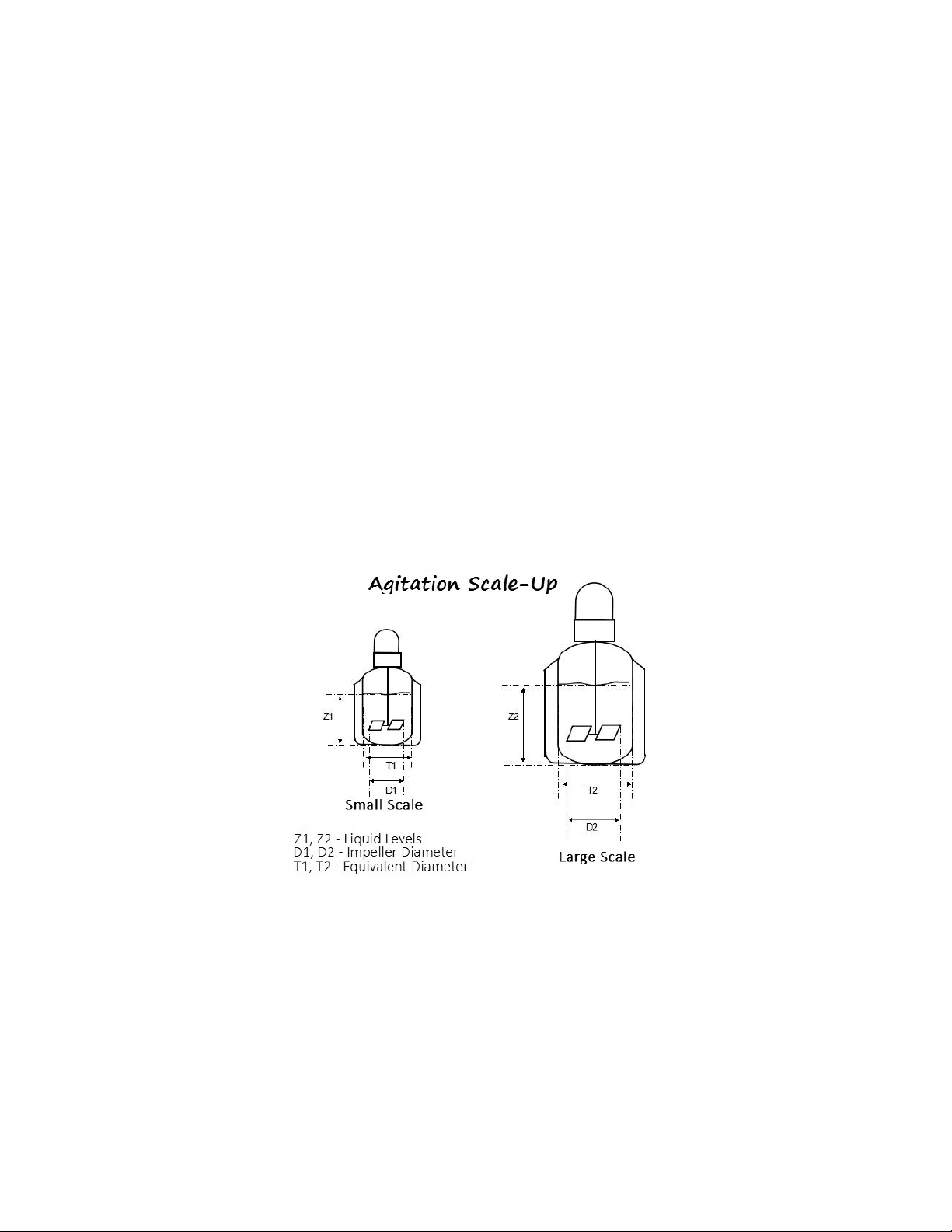

In a Nutshell: As important size reduction is, another unit operation that works oppositely with size reduction is also equally as important. The concept of enlarging the size of the particle is as vital as reducing its particle size in the chemical engineering field. The unit operation that works according to this concept is called the size enlargement operation. This mechanical unit operation involves the use of mechanical forces such as pressure, gravitational and centrifugal forces to reduce the size of particulate solids. Also, temperature can also cause size enlargement of particles. Any industry, or any field that would require a certain size for ease in handling and product specifications would most probably have used a size reduction equipment. This is because there are at least two basic reasons why size enlargement is utilized in particle technology: better flowability and ease in handling. The industries that heavily utilize this operation are the food, agriculture, pharmaceutical, and construction industry. In particle size enlargement operation, there are at least three general methods that are incorporated: agitation, pressure compaction and elevated temperatures. Firstly, agitation is the method that is used by granulators that agglomerate particles by agitating them. Image 1. A schematic of an agitation size enlargement operation Examples of equipment that utilize the concept of agitation to enlarge particle size are the following: drum granulators, disc granulators, mixer granulators, spray dryers and prilling. On one hand, the first three granulators use mechanical means such as introducing centrifugal and gravitational forces to allow particles to stick to each other with the aid of a binding agent. On the other hand, spray dryers and prilling use air instead of mechanical means to give particles a way to agglomerate and stick to each other also with the aid of a binding agent.

Image 2. Mechanical Means of Agitation (Drum Granulators) Image 3. Agitation Induced by Air Flow (Prilling) Secondly, pressure compaction utilizes compaction forces due to pressure differences to coalesce smaller particles into larger ones. This method of size enlargement is commonly used in the pharmaceutical industry where fine particles are coalesced into tablets for ease in transport, handling and most importantly, tablets are more convenient to ingest compared to fine versions of a medicine.