Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

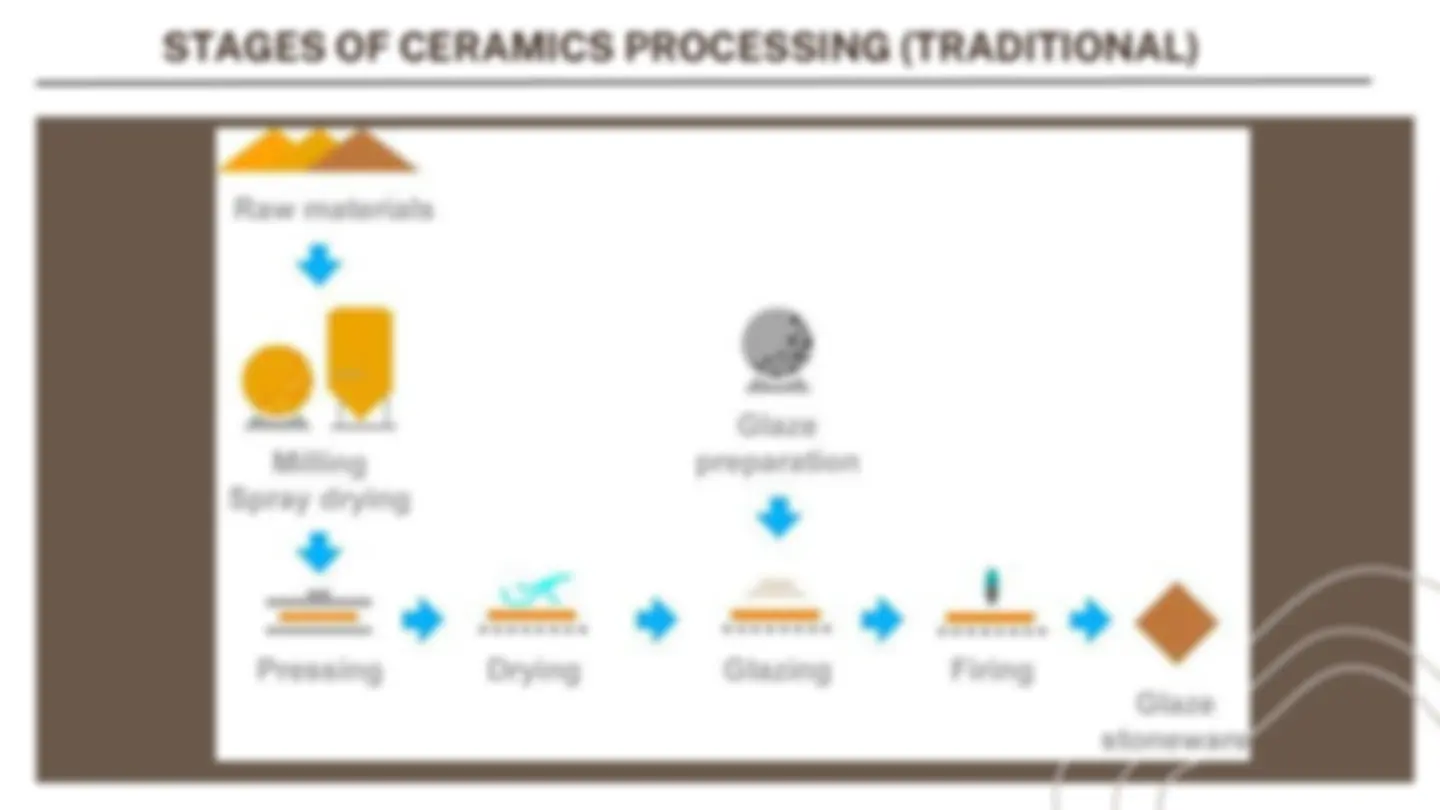

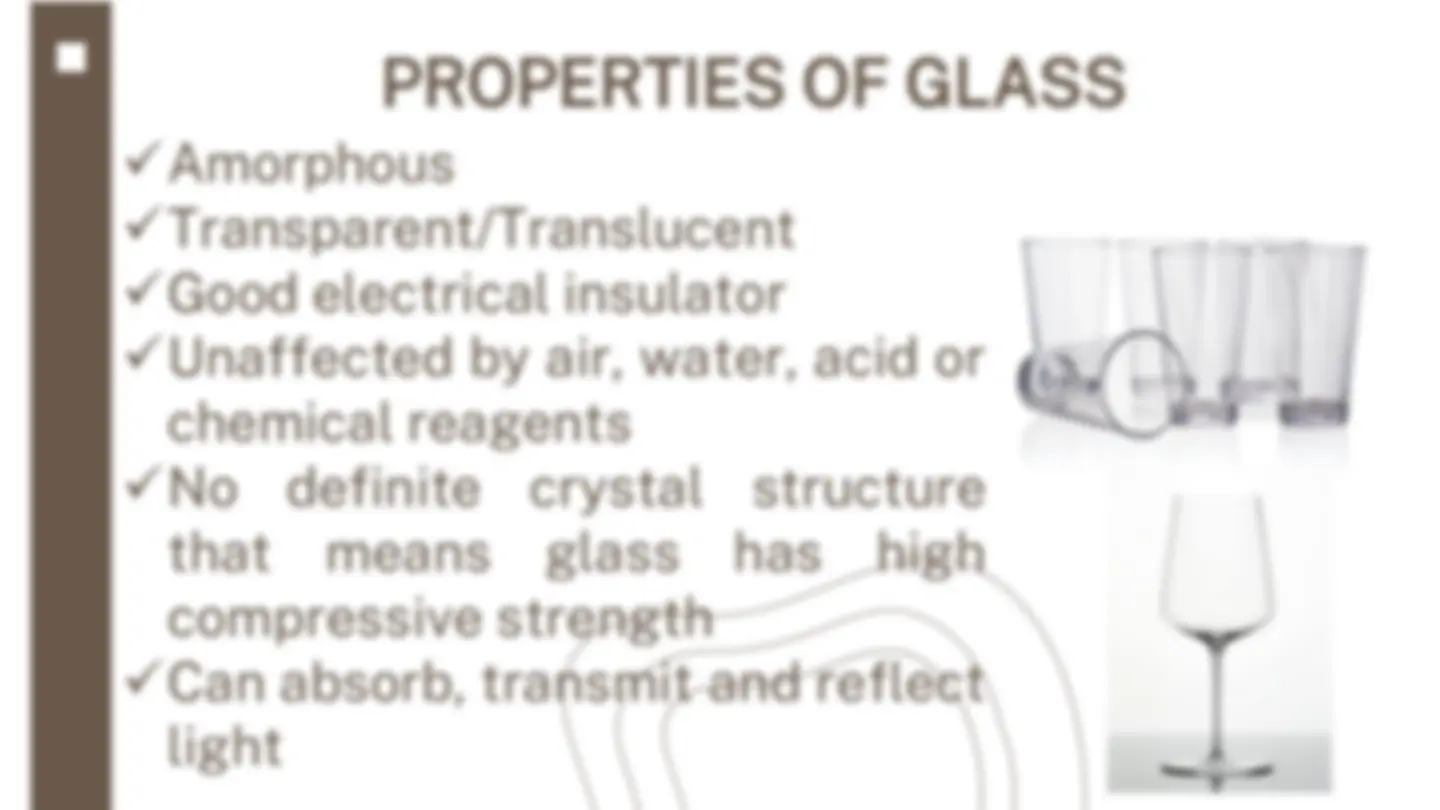

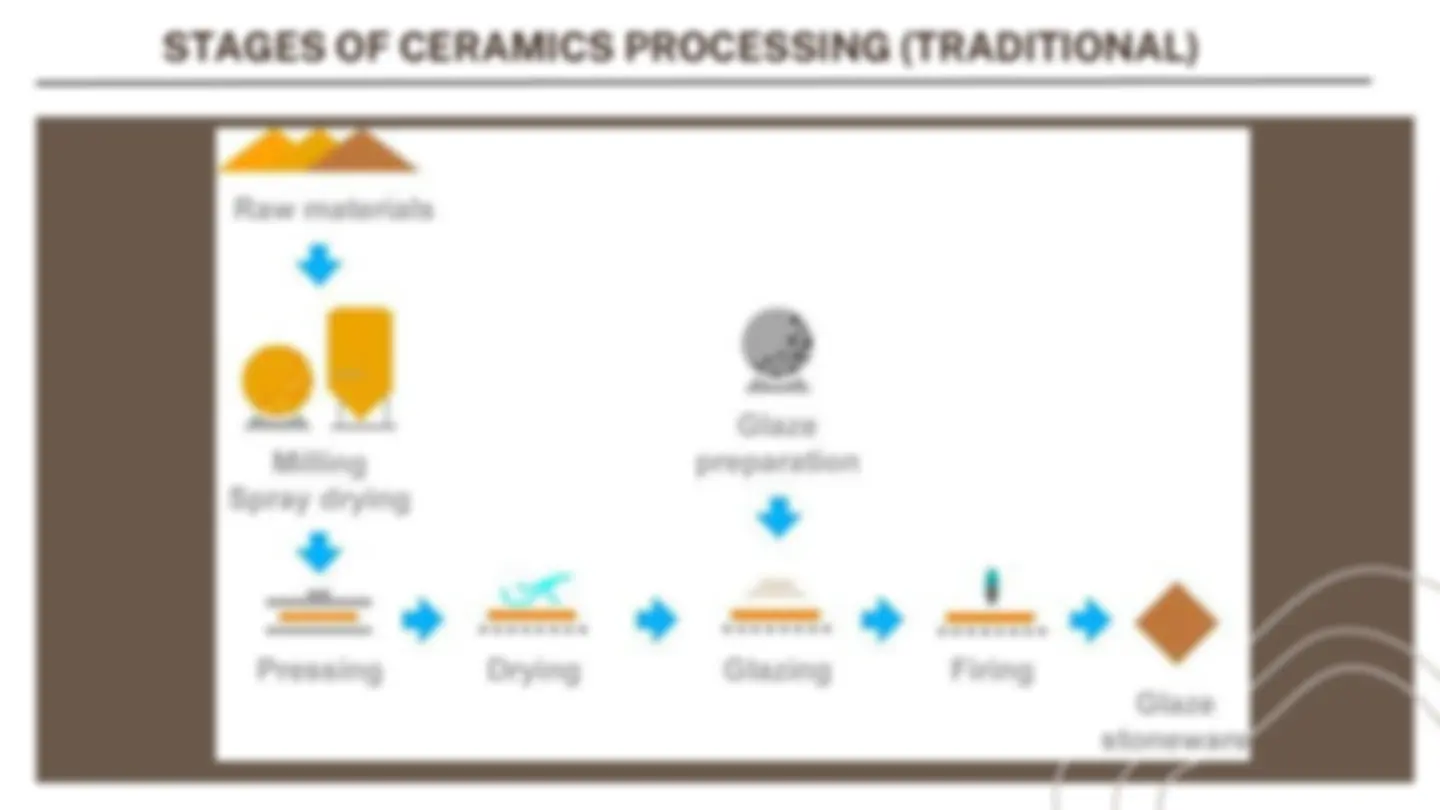

A brief history of glass and ceramics, including their manufacturing processes and uses. It covers the development of glass from ancient times to the present day, including the invention of toughened and wired glass. It also discusses the different types of ceramics, their properties, and uses, including traditional and contemporary ceramics. the manufacturing processes of glass and ceramics, including annealing, flue treatment, oven treatment, quality control, and packing and shipping. It also covers the stages of ceramics processing, including forming, drying, and glazing.

Typology: Study Guides, Projects, Research

1 / 41

This page cannot be seen from the preview

Don't miss anything!

Glass is made from natural and abundant raw materials (silica sand, soda ash and limestone) that are melted at very high temperature to form a new material: glass. RAW MATERIALS Silica Sand Soda Ash Limestone

VARIETIES OF GLASS

GLASS PROCESS MANUFACTURING

Venus of Dolni Vestonice