Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

A portion of a Mechanics of Materials textbook chapter focusing on stress and strain under axial loading. Topics include normal strain, stress-strain test, stress-strain diagrams for ductile and brittle materials, Hooke's Law, elastic vs. plastic behavior, fatigue, and deformations under axial loading. The document also includes sample problems and concept applications.

Typology: Assignments

1 / 31

This page cannot be seen from the preview

Don't miss anything!

Stress and Strain: Axial Loading

Nensi Lakrori, P.E., M.S., LEED AP BD+C

Contents

Stress & Strain: Axial Loading

Stress and Strain: Definitions

Stress-Strain Test

Photo 2.2 Universal test machine used to test tensile specimens.

Photo 2.3 Elongated tensile test specimen having load P and deformed length L > L 0.

https://youtu.be/67fSwIjYJ-E

Stress-Strain Diagram: Ductile

Materials

Photo 2.4 Ductile material tested specimens: (a) with cross-section necking, (b) ruptured.

Fig. 2.6 Stress-strain diagrams of two typical ductile materials.

Cantilever vs. Simply Supported

http://neaco.co.uk/choosing-balconies /

https://www.quora.com/

Structure Failure

The section and material should meet some criteria in the first place, such as:

Stress-Strain Diagram: Brittle

Materials

Fig 2.7 Stress-strain diagram for a typical brittle material.

Photo 2.5 Ruptured brittle materials specimen.

Figure 1: Brittle Cracking of a Wide Flange Beam

Figure 2: Brittle Cracking of a FRC Beam.

Structure Failure: Beams

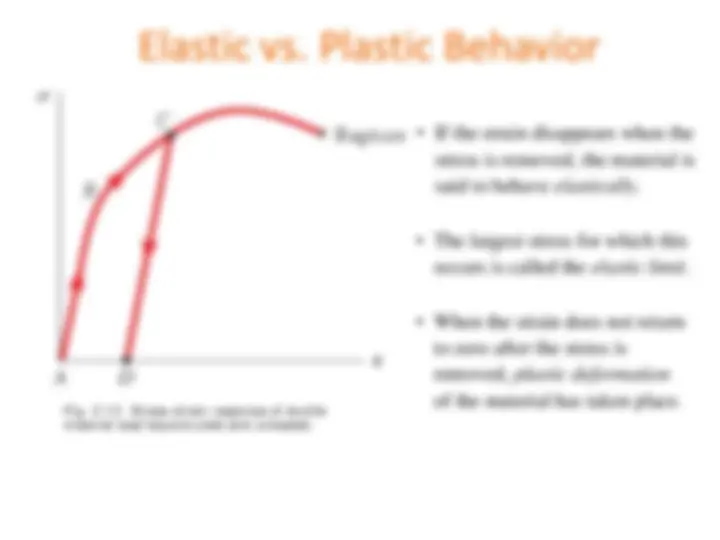

Hooke’s Law: Modulus of Elasticity

Modulusof Elasticity

=YoungsModulusor

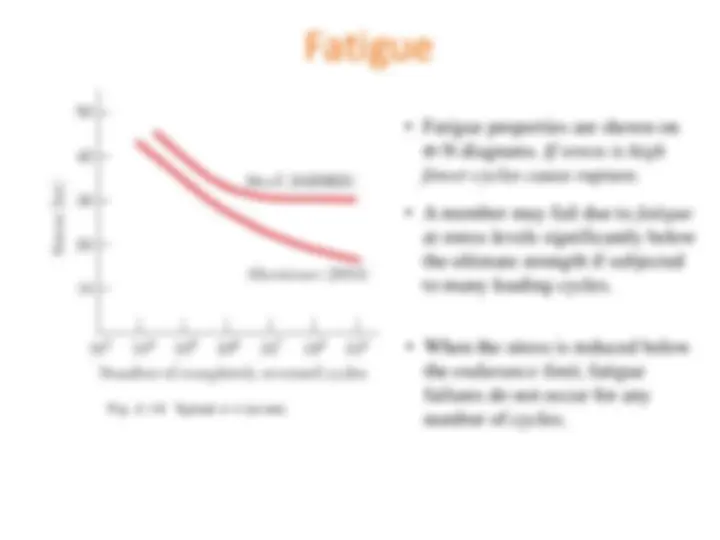

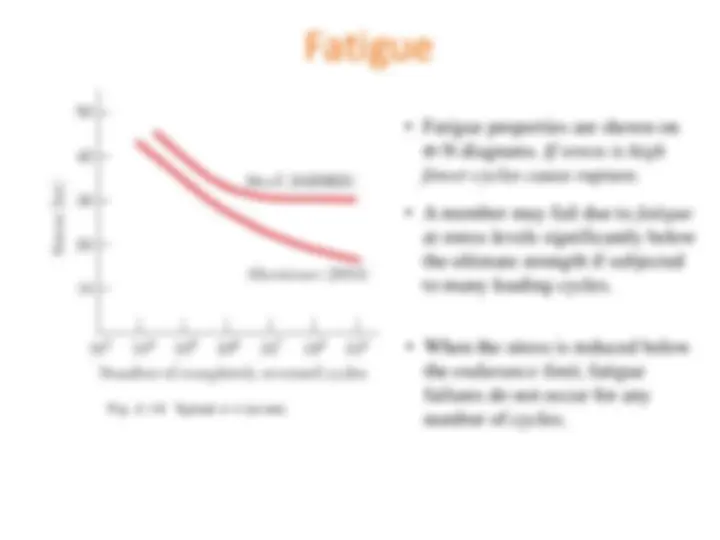

Fatigue

Fig. 2.16 Typical σ -n curves.

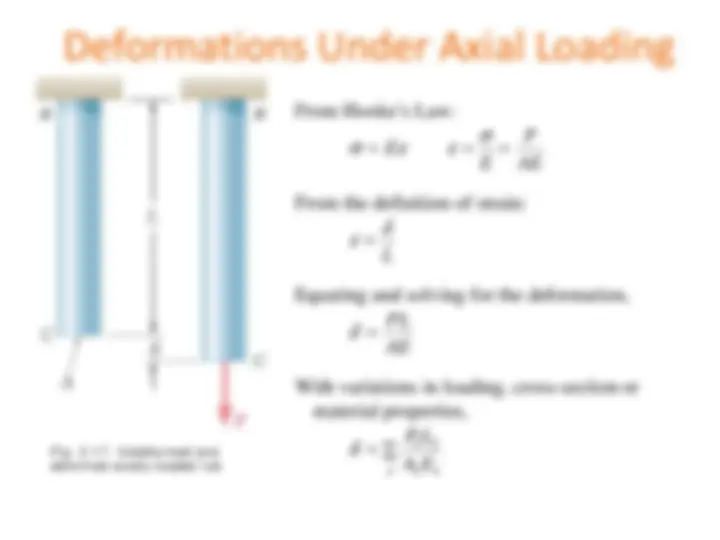

Deformations Under Axial Loading

σ σ ε ε

From Hooke’s Law:

From the definition of strain:

δ ε =

Equating and solving for the deformation,

With variations in loading, cross-section or material properties,

= ∑ i i i

i i A E

deformed axially-loaded rod.